Last Updated on February 3, 2026 by dhruwuttam58@gmail.com

Introduction

Transform your energy independence with precise system sizing and real-world insights. This comprehensive guide delivers precise calculations, regional considerations, and proven strategies for both Indian and U.S. homeowners planning a 50 kWh per day solar panel installation. From DIY tips to professional installation insights, everything you need is here.

Table of Contents

Quick Answer: Understanding How Many Solar Panels for 50 kWh Per Day

To generate 50 kWh per day, you typically need:

- 400W panels: 29-32 panels (depending on sunlight hours)

- 300W panels: 39-42 panels

- System size: 12-15 kW capacity

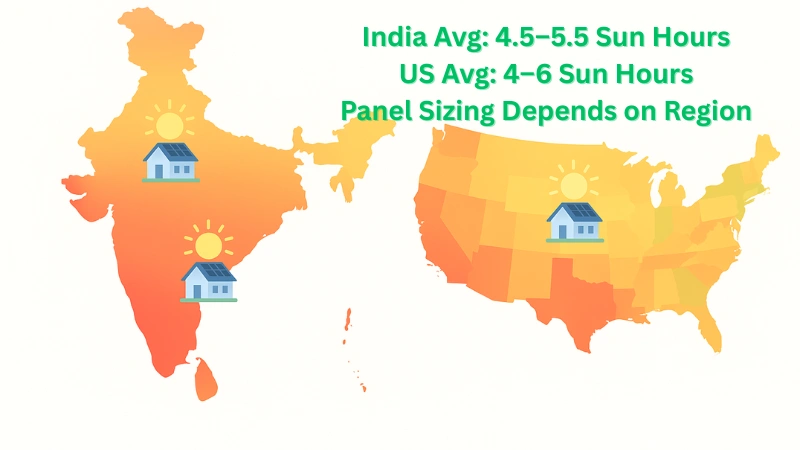

The exact number varies significantly by location—Phoenix homeowners might need just 28 panels, while Delhi residents could require 35+ panels due to regional sunlight differences.

Calculate your precise requirements with our Solar ROI Calculator — the 50 kWh solar system size calculator provides instant sizing, cost analysis, and payback projections.

Learn more about best practices in solar sizing and ROI from the U.S. Department of Energy.

Understanding 50 kWh Daily Energy Consumption

A how many solar panels for 50 kWh per day scenario represents substantial energy usage that varies dramatically by region and lifestyle. In the U.S., this exceeds the national average of 29 kWh/day by 72%, while in India, it’s nearly 4x the typical urban household consumption.

Below are Typical Usage Profiles: for 50kWh Use:

Knowing how many solar panels you need to produce 50 kWh per day starts with understanding your daily usage patterns and energy goals.

| Location Type | Daily kWh | Primary Loads |

|---|---|---|

| Large U.S. Suburban Home | 48-55 | Central HVAC, pool pump, EV charging, major appliances |

| Indian Urban Bungalow | 40-52 | Multiple ACs, water heating, business equipment |

| Small Commercial Space | 45-60 | Lighting, refrigeration, computers, machinery |

| Off-Grid Farmhouse | 35-50 | Water pumps, grain storage, workshop tools |

Regional Energy Context:

- California homes averaging 50 kWh face monthly bills of $200-400 before solar

- Delhi households at this consumption level pay ₹12,000-18,000 monthly

- Rural applications often combine residential + agricultural loads

Load Distribution Patterns:

Most 50 kWh consumers show distinct usage peaks:

- Morning surge (6-9 AM): Water heating, cooking appliances

- Afternoon peak (2-5 PM): Air conditioning, business operations

- Evening demand (6-10 PM): Lighting, entertainment, EV charging

Understanding these patterns helps optimize solar system sizing and battery storage requirements for maximum efficiency.

Step-by-Step Calculation Method

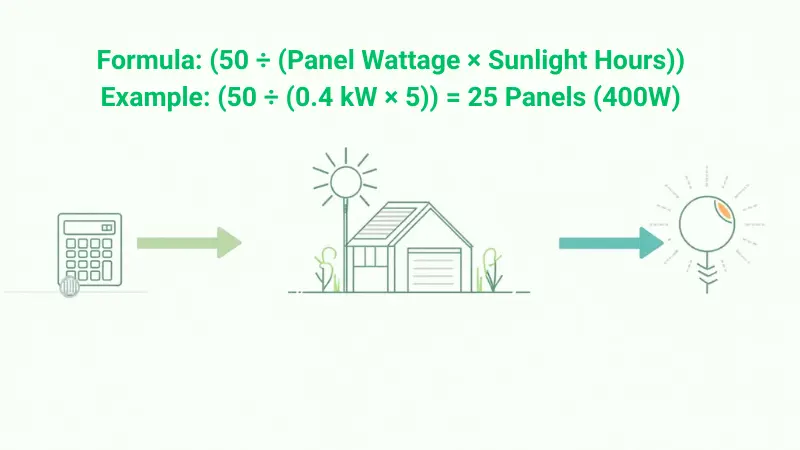

Master Formula:

Required Panels = Daily kWh ÷ (Panel Wattage × Peak Sun Hours × System Efficiency)

Component Breakdown:

- Daily Energy Need: 50 kWh

- Panel Wattage: 300W, 400W, or custom

- Peak Sun Hours: Location-specific (not daylight hours!)

- System Efficiency: 85% (accounts for inverter losses, wiring, dust)

Peak Sun Hours by Major Cities:

Peak sun hours are crucial for determining how many 400W solar panels are needed to produce 50 kWh. For example:

| City | Annual Average | Summer Peak | Winter Low |

|---|---|---|---|

| Phoenix, AZ | 6.5 | 7.8 | 4.2 |

| Miami, FL | 5.8 | 6.4 | 4.8 |

| Denver, CO | 5.2 | 6.1 | 3.9 |

| Delhi, India | 4.7 | 5.6 | 3.8 |

| Mumbai, India | 4.8 | 5.2 | 4.1 |

| Bangalore, India | 5.0 | 5.5 | 4.3 |

Worked Examples:

Phoenix Example (400W panels):

50 kWh ÷ (0.4 kW × 6.5 hours × 0.85) = 22.6 → 23 panels

Delhi Example (300W panels):

50 kWh ÷ (0.3 kW × 4.7 hours × 0.85) = 41.7 → 42 panels

You don’t need to guess—our 50 kWh solar system size calculator simplifies the entire process by using your local sunlight hours and preferred panel wattage.

Seasonal Adjustment Strategy:

- Size for the worst-case month to ensure year-round sufficiency

- Add 10-15% buffer for monsoon/winter reductions

- Consider battery backup for critical loads during low-production periods

Advanced Calculations:

- Temperature coefficients: Panels lose 0.4-0.5% efficiency per °C above 25°C

- Shading losses: Can reduce output by 5-25% depending on obstruction patterns

- Panel degradation: 0.5-0.8% annual efficiency decline over 25-year lifespan

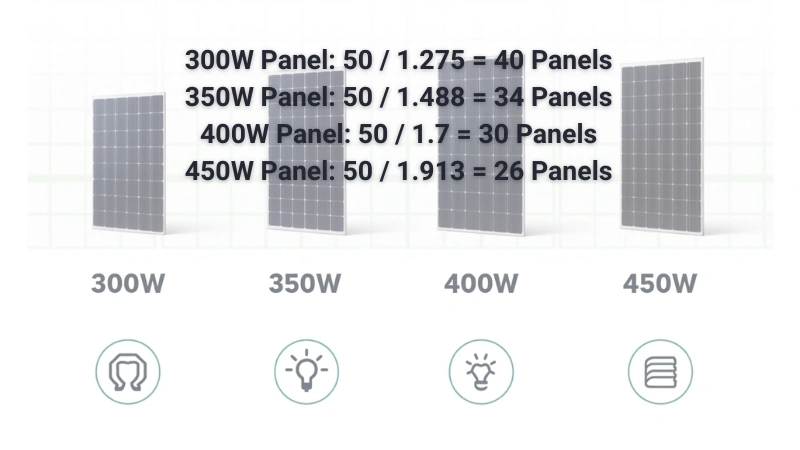

Panel Wattage vs Quantity Breakdown

2026 Panel Efficiency Comparison:

| Panel Type | Wattage | Efficiency | Panels for 50 kWh | Roof Area Required |

|---|---|---|---|---|

| Monocrystalline | 400W | 20–22% | 29–32 | 580–640 sq ft |

| Monocrystalline | 450W | 21–23% | 26–29 | 520–580 sq ft |

| Polycrystalline | 300W | 17–19% | 39–42 | 780–840 sq ft |

| Bifacial | 500W | 22–24% | 23–26 | 460–520 sq ft |

Higher wattage panels mean fewer panels and less roof space, but may increase upfront costs. Climate, available space, and budget will determine the optimal number of solar panels needed to produce 50 kWh per day.

For example, if you’re wondering how many 400W solar panels are needed to produce 50 kWh, the answer is roughly 30 panels, assuming 5 hours of sunlight per day.

Cost-Benefit Analysis:

Higher wattage panels reduce installation complexity but increase per-panel costs:

400W vs 300W Panel Economics (12 kW system):

- 400W system: 30 panels × $250 = $7,500 in panels

- 300W system: 40 panels × $200 = $8,000 in panels

- Labor savings: $800-1,200 fewer mounting points and connections

- Roof space savings: 25% reduction in required area

DIY Installation Considerations:

- 300W panels: Easier handling (40-45 lbs each), standard roof penetrations

- 400W+ panels: Heavier (50-55 lbs), require stronger mounting hardware

- Electrical planning: Higher wattage reduces the string length calculations complexity

State-Specific Panel Preferences:

- California: 400W+ panels dominate due to limited roof space, high labor costs

- Texas: Mix of 300-400W based on available roof area and cost priorities

- India: 300-330W panels remain popular due to cost sensitivity and adequate roof space

“If ground or roof space is limited, explore wall-mounted solar panel setups that optimize vertical alignment.”

Performance in Different Climates:

- Hot climates (Phoenix, Delhi summer): Higher wattage panels perform better due to reduced panel count and heat concentration

- Moderate climates (California coast): Panel wattage less critical, cost becomes the primary factor

- Dusty environments (Rajasthan, Arizona): More panels = more cleaning maintenance

System Components Beyond Solar Panels

Complete 50 kWh System Architecture:

Core Components:

- Solar Array (12-15 kW capacity)

- Inverter System (10-12 kW hybrid or string)

- Battery Storage (20-60 kWh depending on backup needs)

- Monitoring System (performance tracking and optimization)

- Safety Equipment (breakers, disconnects, surge protection)

Inverter Selection for 50 kWh Systems:

| Inverter Type | Capacity | Price Range (US) | Price Range (India) | Best For |

|---|---|---|---|---|

| String Inverter | 12 kW | $3,000–5,000 | ₹180,000–300,000 | Grid-tied, minimal shading |

| Power Optimizers | 12 kW | $4,500–7,000 | ₹270,000–420,000 | Partial shading, complex roofs |

| Microinverters | 12 kW | $6,000–9,000 | ₹360,000–540,000 | Maximum flexibility, monitoring |

| Hybrid Inverter | 12 kW | $5,000–8,000 | ₹300,000–480,000 | Battery backup integration |

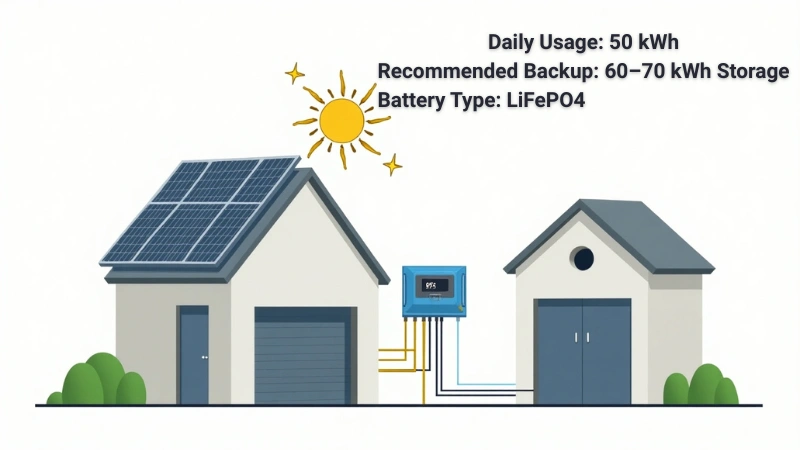

Solar Battery Backup Requirements: Key Factors

Planning for solar battery backup requirements is crucial, especially if you want your 50 kWh solar system to provide consistent power during outages or at night.

When calculating solar battery backup requirements, consider:

- 4-6 hours (essential loads): 15-20 kWh battery

- 8-12 hours (partial home): 25-35 kWh battery

- 24+ hours (full off-grid): 50-70 kWh battery

Battery Technology Comparison:

- Lithium Iron Phosphate: 10-15 years lifespan, 90% DoD, premium cost

- Lead Acid: 3-5 years lifespan, 50% DoD, budget option

- Lithium-Ion: 8-12 years lifespan, 80-95% DoD, mainstream choice

“Choosing the right inverter is crucial. Learn how to avoid common inverter installation mistakes to prevent inefficiencies.”

We compare lithium vs lead-acid options based on solar battery backup requirements for a 50 kWh setup.

Advanced Component Features:

Modern 50 kWh systems increasingly include:

- Smart load management: Automatic load shedding during low production

- Grid-interactive capabilities: Frequency regulation, demand response participation

- Predictive maintenance: IoT sensors for component health monitoring

- Mobile integration: Smartphone apps for system control and optimization

India vs US Installation Considerations

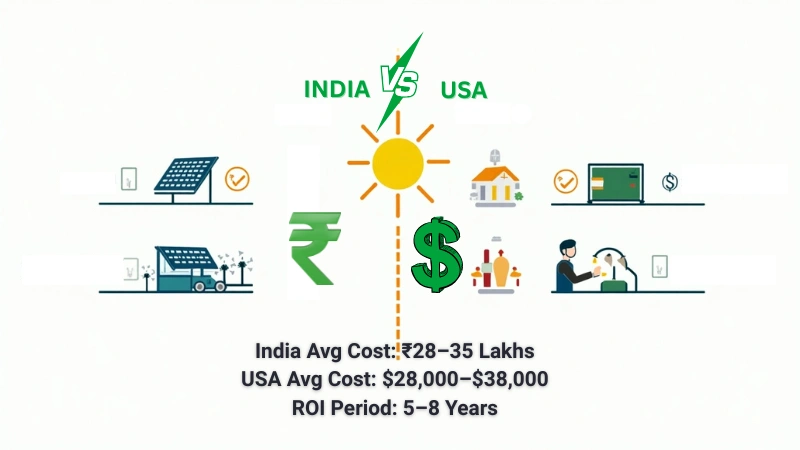

Regional Cost Analysis (2026):

| Component | India Cost | US Cost | Key Differences |

|---|---|---|---|

| 12 kW Solar Array | ₹540,000–720,000 | $18,000–30,000 | Indian bureaucracy factor |

| Hybrid Inverter | ₹300,000–480,000 | $5,000–8,000 | Similar technology costs |

| 20 kWh Battery | ₹800,000–1,400,000 | $16,000–28,000 | India’s battery costs are higher |

| Installation Labor | ₹80,000–150,000 | $8,000–15,000 | 5:1 labor cost ratio |

| Permits & Inspection | ₹20,000–50,000 | $1,500–4,000 | India bureaucracy factor |

While prices vary, the 50 kWh solar system in India can be significantly lower than in the U.S. due to labor and component sourcing differences.

Climate Adaptation Strategies:

India-Specific Challenges:

- Monsoon planning: 40-60% output reduction June-September

- Dust accumulation: Monthly cleaning is essential, 15-25% efficiency loss without maintenance

- Grid instability: Voltage fluctuations require robust inverter protection

- Space constraints: Urban rooftops average 600-1,200 SQ ft vs 2,000+ SQ ft in US suburbs

US Regional Variations:

- California: Strict interconnection standards, mandatory rapid shutdown equipment

- Texas: Extreme heat considerations, panel cooling strategies are essential

- North East: Snow load calculations, steeper tilt angles for winter optimization

- South East: Hurricane-rated mounting systems, corrosion-resistant hardware

Seasonal Performance Optimization:

Summer Strategies:

- India: Tilt panels 5-10° flatter than latitude to maximize summer production

- US Southwest: Focus on panel cooling, adequate ventilation spacing

Winter Adaptations:

- Northern US: Steeper tilt (latitude + 15°) for improved winter collection

- India: Minimal adjustment needed except in northern plains regions

Installation Workforce Differences:

- India: Mixed skill levels, emphasis on cost-effective techniques, growing certification programs

- US: Licensed electricians required, standardized safety protocols, and higher quality consistency

Financing and Incentive Landscapes:

- India: 20-40% MNRE subsidies, state-specific additional incentives

- US: 30% federal ITC through 2026, state rebates vary dramatically

Regional cost, climatic adaptation, and incentive differences play a strong role in your system’s price, design, and output.

- Solar arrays in Rajasthan (India) and Arizona (U.S.) see higher returns due to abundant sunlight

- State/central subsidies in India, and U.S. tax credits, can reduce costs by 20–40%

- Dust and monsoon in India, snow and cloud cover in northern U.S. states, influence site layout and maintenance

- The 50 kWh solar system cost in India will differ greatly, state-by-state and brand-by-brand, so always compare multiple local quotes

For more on Indian solar regulations and incentives, see MNRE India.

Off-Grid vs Grid-Tied for 50 kWh Systems

When planning how many solar panels for 50 kWh per day, consider the system design:

Comprehensive System Comparison:

| Aspect | Grid-Tied | Off-Grid | Hybrid |

|---|---|---|---|

| Initial Cost | $25,000–35,000 | $45,000–70,000 | $35,000–55,000 |

| Battery Required | No | Yes (50–70 kWh) | Yes (15–30 kWh) |

| Grid Dependence | High | None | Moderate |

| Backup Power | No | Yes | Yes |

| Net Metering | Yes | N/A | Limited |

| Maintenance | Low | High | Moderate |

Detailed Use Case Analysis:

Grid-Tied Advantages:

- Lower upfront costs: No battery investment reduces initial expense by $15,000-25,000

- Net metering benefits: Sell excess production at retail rates in favorable states

- Simplified maintenance: Fewer system components, reduced complexity

- Unlimited grid backup: Never worry about running out of stored power

Grid-Tied Limitations:

- Blackout vulnerability: System shuts down during outages for safety

- Rate structure risks: Time-of-use rates and reduced net metering credits

- Grid dependency: Still reliant on utility infrastructure

Off-Grid Benefits:

- Complete energy independence: No utility bills or grid connection fees

- Blackout immunity: Continuous power regardless of grid status

- Remote location viability: Perfect for properties without grid access

- Energy security: No exposure to rate increases or policy changes

“If you’re building a fully independent setup, explore our solar power survival kit designed for off-grid living.”

Off-Grid Challenges:

- Higher initial investment: Battery systems add 40-60% to total cost

- Capacity limitations: System must handle peak loads without grid support

- Battery replacement: Major expense every 8-12 years

- Generator backup: Often needed for extended cloudy periods

Hybrid System Sweet Spot:

Modern hybrid systems offer optimal flexibility for 50 kWh consumers:

Hybrid Configuration Example:

- 12 kW solar array: Handles daytime loads plus battery charging

- 20 kWh battery: 6-8 hours backup for essential circuits

- Grid connection: Net metering for excess production, backup during extended outages

- Smart controls: Automatic switching between solar, battery, and grid power

Financial Performance Comparison (25-year lifecycle):

| System Type | Initial Cost | Annual Savings | Total ROI |

|---|---|---|---|

| Grid-Tied | $32,000 | $3,600 | 280% |

| Off-Grid | $58,000 | $4,800 | 207% |

| Hybrid | $42,000 | $3,800 | 227% |

Calculations based on $0.12/kWh electricity rates, 3% annual rate increases.

Real-World 50 kWh Solar Setups

Case Study 1: Phoenix Suburban Mansion

- Location: Scottsdale, Arizona (6.8 peak sun hours)

- System: 28 × 400W panels (11.2 kW), SolarEdge optimizers

- Production: 55-65 kWh/day average, 45 kWh winter minimum

- Components: SE7600H inverter, Tesla Powerwall 2 (13.5 kWh)

- Cost: $28,000 after federal tax credit

- Results: 95% grid independence, $380/month savings

- Lessons: Microinverters solved shading from palm trees, east-west split array maximized roof usage

Case Study 2: Delhi Corporate Residence

- Location: Greater Noida (4.8 peak sun hours average)

- System: 38 × 330W panels (12.5 kW), centralized string inverter

- Production: 45-55 kWh/day summer, 30-35 kWh monsoon

- Components: Growatt 12 kW hybrid inverter, 16 kWh LiFePO4 battery

- Cost: ₹850,000 after MNRE subsidy

- Results: 80% annual grid independence, ₹14,000/month savings

- Challenges: Dust storms required bi-weekly cleaning, and grid voltage fluctuations needed a stabilizer

Case Study 3: Rural Texas Ranch

- Location: Hill Country, Texas (5.6 peak sun hours)

- System: 32 × 375W panels (12 kW), ground-mounted tracking

- Production: 60-70 kWh/day with tracking, 20% boost over fixed

- Components: Outback FlexPower system, 40 kWh battery bank

- Cost: $42,000 complete off-grid installation

- Applications: Well pumps, barn operations, main residence

- Innovations: Automatic tracker adjustment, propane generator backup

Case Study 4: Mumbai High-Rise Cooperative

- Location: Powai, Mumbai (4.9 peak sun hours)

- System: 45 × 320W panels (14.4 kW) across multiple buildings

- Production: 50-60 kWh/day supporting 8 apartments

- Components: ABB string inverters, shared battery system

- Cost: ₹920,000 total, ₹115,000 per unit after subsidy

- Management: Housing society agreement, proportional savings distribution

- Innovation: Elevator load balancing, common area lighting priority

Case Study 5: California Wine Country Estate

- Location: Napa Valley (5.4 peak sun hours)

- System: 26 × 450W panels (11.7 kW), integrated with Tesla Solar Roof

- Production: 52-58 kWh/day, aesthetic integration priority

- Components: Tesla Powerwall 3 (13.5 kWh), premium monitoring

- Cost: $38,000 after incentives (aesthetic premium included)

- Features: Wine cellar climate control, EV charging integration

- Results: Net-positive energy, $420/month utility credit during peak production

Case Study 6: Bangalore IT Professional Home

- Location: Electronic City, Bangalore (5.1 peak sun hours)

- System: 35 × 350W panels (12.25 kW), south-facing optimized

- Production: 48-55 kWh/day, typical, excellent year-round consistency

- Components: Luminous hybrid inverter, 12 kWh tubular battery backup

- Cost: ₹780,000 after Karnataka state incentives

- Loads: Home office, EV charging, swimming pool filtration

- Achievement: First net-zero home in the IT corridor development

Cost Analysis & ROI Calculator

Comprehensive Cost Breakdown (50 kWh System – 2026):

50 kWh Solar System Cost in India (2026 Estimates):

| Component | Budget Option | Premium Option | Percentage of Total |

|---|---|---|---|

| Solar Panels (12 kW) | ₹420,000 | ₹660,000 | 35–45% |

| Hybrid Inverter | ₹240,000 | ₹420,000 | 20–25% |

| Battery System (20 kWh) | ₹600,000 | ₹1,200,000 | 40–50% |

| Mounting & Installation | ₹120,000 | ₹180,000 | 8–12% |

| Permits & Commissioning | ₹30,000 | ₹60,000 | 2–4% |

| Total | ₹1,410,000 | ₹2,520,000 | 100% |

The 50 kWh solar system in India typically ranges from ₹28 to ₹35 lakhs, depending on quality, brand, and installation type.

US Pricing Structure:

| Component | Standard | Premium | Percentage of Total |

|---|---|---|---|

| Solar Panels (12 kW) | $18,000 | $30,000 | 40–50% |

| Hybrid Inverter | $6,000 | $10,000 | 15–20% |

| Battery System (20 kWh) | $16,000 | $28,000 | 35–45% |

| Installation Labor | $8,000 | $12,000 | 15–20% |

| Permits & Interconnection | $2,000 | $4,000 | 3–5% |

| Total | $50,000 | $84,000 | 100% |

State-by-State Cost Variations (US):

- California: $2.30-2.91/W installed, high labor costs offset by competition

- Texas: $2.38-2.75/W installed, lower labor but limited incentives

- Arizona: $2.07-2.36/W installed, optimal conditions reduce system size needs

- New York: $2.83-3.10/W installed, generous state incentives offset high costs

Indian State Variations:

- Rajasthan: ₹42-48/W, good solar resource, established supply chain

- Maharashtra: ₹45-52/W, strong incentives, competitive market

- Karnataka: ₹44-50/W, tech hub advantages, progressive policies

- Tamil Nadu: ₹46-54/W, industrial demand, established manufacturing

Monthly Cash Flow Analysis:

Year 1-5 Performance:

- India: ₹12,000-15,000 monthly savings, ₹2,500 loan payment = ₹9,500 net positive

- US: $350-450 monthly savings, $380 loan payment = slight negative to positive

Year 6-10 Performance (loan paid off):

- India: Full ₹12,000-15,000 monthly savings to the owner

- US: Full $350-450 monthly savings, accelerating with utility rate increases

Payback Period Analysis:

- Grid-tied only: 4-6 years with subsidies

- Hybrid system: 6-8 years, including battery value

- Off-grid rural: 3-5 years when replacing generator costs

US Scenarios:

- Grid-tied: 6-9 years, depending on state incentives

- Hybrid: 8-12 years, factoring backup value

- Premium markets: 5-7 years in high electricity cost areas

Advanced ROI Factors:

- Property value increase: 4-8% premium for solar homes

- Insurance cost impacts: Slight increase for system coverage, decrease for backup power

- Maintenance reserves: $500-1,000 annually for optimal performance

- Technology refresh: Inverter replacement ($3,000-5,000) at 10-12 years

Monthly breakdowns show Indian homeowners typically save ₹12,000–₹16,000 and ROI after 5–7 years, accounting for the 50 kWh solar system in India with subsidy. U.S. owners typically save $350–$500/month, with 6–9 year paybacks depending on rate and net metering.

The 50 kWh solar system in India varies by location, panel brand, and inverter setup.

Model your timeline and monthly payoff potential with our Solar ROI Calculator—your 50 kWh solar system size calculator for 2025 and beyond.

Common Mistakes to Avoid

Critical Design Errors:

1. Under-sizing for Peak Demands

Many homeowners calculate based on average consumption but fail to account for peak usage periods. A 50 kWh daily average might include 8-10 kWh afternoon peaks that require 12-15 kW of solar capacity to handle without grid support.

2. Ignoring Seasonal Variations

- Mistake: Sizing for summer production in northern climates

- Solution: Design for the worst-case winter month, add a 15-20% buffer

- India-specific: Account for 40-50% monsoon production reduction

3. Poor Component Matching

- Inverter under-sizing: Using a 10 kW inverter for a 12 kW array loses production

- Battery voltage mismatch: 24V panels with a 48V battery system create inefficiencies

- Wire gauge errors: Undersized DC cables cause power losses and safety hazards

Installation Pitfalls:

1. Inadequate Roof Assessment

- Structural capacity: 50 kWh systems weigh 2,000-3,000 lbs installed

- Shading analysis: Morning shadows reduce production more than afternoon shadows

- Roof age: Install solar before major roof replacement needs

2. Orientation and Tilt Mistakes

- Fixed installations: Compromise between summer/winter optimal angles

- East-west splits: Can increase daily production despite lower peak output

- Tracking systems: Add complexity but boost output 20-25% in open areas

Maintenance Oversights:

1. Cleaning and Inspection Neglect

- Dust accumulation: 15-25% output loss without regular cleaning

- Connection corrosion: Annual inspection prevents safety hazards and efficiency loss

- Battery maintenance: Lead-acid systems require monthly water checks

2. Monitoring System Gaps

- Production tracking: Identify underperforming panels quickly

- Consumption analysis: Optimize load scheduling for maximum solar utilization

- Alert systems: Immediate notification of system faults or failures

Financial and Regulatory Mistakes:

1. Permit and Code Compliance

- Building permits: Required for structural modifications and electrical work

- Utility interconnection: Proper applications prevent costly delays

- Insurance notification: Failure to inform insurers can void coverage

2. Poor Financing Decisions

- Oversized loans: Include realistic maintenance and replacement reserves

- Missing incentives: File tax credits and rebate applications promptly

- Lease vs purchase: Understand long-term implications for property value

Review solar inverter installation mistakes to prevent costly system failures.

Frequently Asked Questions

How many 400W solar panels do I need for 50 kWh per day?

You need approximately 29-32 × 400W solar panels for 50 kWh daily production, depending on your location’s peak sun hours. In sunny regions like Phoenix (6.5 sun hours), 29 panels suffice, while areas with less sun, like Boston (4.2 sun hours), require 32+ panels. This calculation assumes 85% system efficiency, accounting for inverter losses and environmental factors.

What size inverter do I need for a 50 kWh solar system?

A 12 kW hybrid inverter is optimal for most 50 kWh/day systems, providing 120% of the solar array capacity to handle peak production and battery charging simultaneously. String inverters work for simple installations, while hybrid inverters enable battery integration and backup power. Consider a 15 kW capacity if adding future expansion or operating large motor loads.

How much battery storage is required for 50 kWh daily?

Battery requirements vary by backup duration needs: 15-20 kWh covers essential loads for 6-8 hours, 25-35 kWh provides 8-12 hours of partial home backup, and 50-70 kWh enables full off-grid operation for 24+ hours. Lithium-ion batteries offer 90% usable capacity while lead-acid systems typically limit to 50% depth of discharge for longevity.

What’s the cost of a 50 kWh solar system in India?

A complete 50 kWh/day system costs ₹1.4-2.5 million before subsidies, varying by component quality and installation complexity. With MNRE subsidies (₹78,000) and state incentives, net costs range from ₹1.2-2.2 million. Grid-tied systems cost 30-40% less than hybrid systems with battery backup. Financing options typically offer 8-12% interest rates with 5-7 year terms.

Can I install a 50 kWh solar system myself?

DIY installation is possible for experienced homeowners with electrical knowledge, potentially saving $8,000-15,000 in labor costs. However, grid-tied systems require licensed electrician certification for utility interconnection and code compliance. Off-grid systems offer more DIY flexibility but need careful planning for safety and performance. Most homeowners hire professionals for complex 50 kWh installations due to size and complexity.

What roof space is needed for 50 kWh solar panels?

A 50 kWh system requires 580-840 square feet of unobstructed roof space, depending on panel wattage. 400W panels need approximately 580-640 sq ft, while 300W panels require 780-840 sq ft. Account for setbacks (3 feet from edges), spacing between rows (4-6 feet), and obstacles like chimneys or vents. Ground-mount systems need 1,200-1,500 sq ft to accommodate spacing and access requirements.

How long do 50 kWh solar systems last?

Solar panels carry 25-year warranties and typically produce electricity for 30+ years with a gradual efficiency decline (0.5-0.8% annually). Inverters last 10-15 years and batteries 5-15 years, depending on type—lithium-ion batteries last 10-15 years while lead-acid systems require replacement every 3-5 years. Total systems’ lifespan exceeds 25 years with component replacements as needed.

What permits are required for a 50 kWh solar installation?

In the US, you need building permits from local authorities, electrical permits for grid connection, and utility interconnection agreements for net metering. India requires DISCOM approval (NOC), electrical inspector certification for large systems, net metering agreements, and municipal building permits for commercial installations. Processing times vary from 2-8 weeks, depending on jurisdiction complexity and system size.

By now, you should have a clear understanding of how many solar panels for 50 kWh per day you’ll need and what other components make up a complete setup.

Conclusion

This comprehensive guide equips you with all of the information and resources required to plan, size, and install a 50 kWh/day solar system by 2026. Use our Solar ROI Calculator for personalized estimates while connecting with certified installers who can make your energy independence goals come to life.

Whether you’re planning a rooftop setup or a large ground-mount system, calculating how many solar panels for 50 kWh per day is the first step to energy independence.